In addition to bell-founding, a number of ‘village industries’ flourished and then faded out in Aldbourne at different times between the 18th century and the early decades of the 20th century. One of these was chair-making.

In addition to bell-founding, a number of ‘village industries’ flourished and then faded out in Aldbourne at different times between the 18th century and the early decades of the 20th century. One of these was chair-making.

Seven chair-makers lived in Aldbourne in 1851 (including five members of the Palmer family), and Thomas Orchard, a thatcher and woodman, started to produce hand-made chairs about 4 years later. By 1867, Albert Bray was working with Orchard, preparing the wood for chair-making in a large saw-pit near to Barn House in Castle Street where he lived; and in 1887, Thomas Orchard opened a chair factory in a thatched barn at Glebe Farm in South Street, roughly where One Ash now stands.

By the late 19th century, Orchard’s business had about 40 employees and in the early 20th century produced about 100 chairs a week.

The legs and stretchers for the chairs were made from beech or birch stems brought in from the neighbouring woods; while elms from the Chase were cut into thick planks for the seats and the flat parts of the backs.

In 1910, a set of six Windsor chairs made in Aldbourne could be bought for 18 shillings – 90p in today’s money. However, by the 1920s, competition from the more mechanised factories such as those at High Wycombe meant that even these prices could not be sustained, and finished chairs were sold for 2s. 4d (about 12p) each – though an armchair would cost as

much as 10s. 6d. (52½p).

The competition led to the decline of the business, which was down to 12 workers in 1921, and to the eventual closure of the factory in 1927.

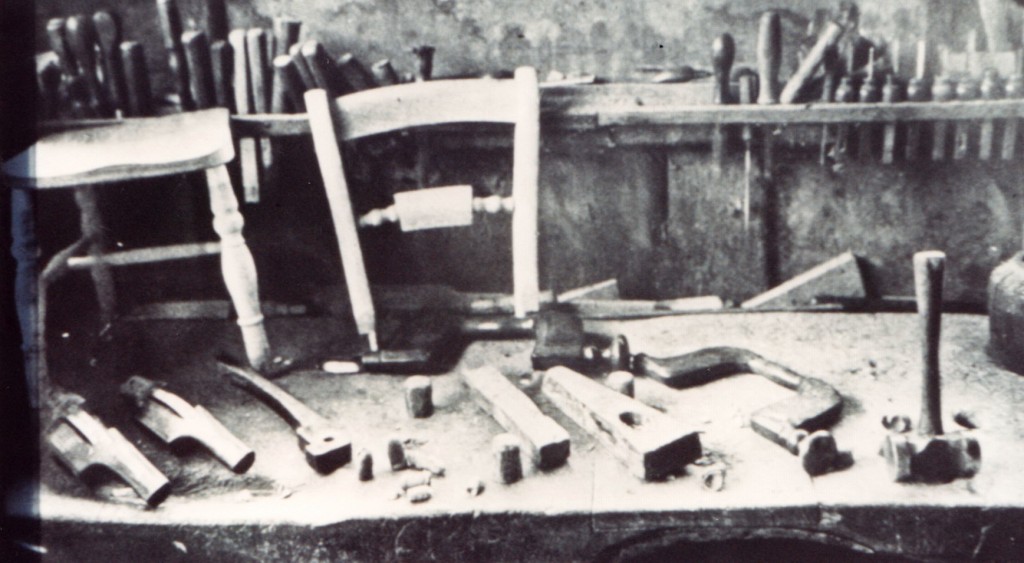

The workshop in South Street in which the Windsor chairs were made

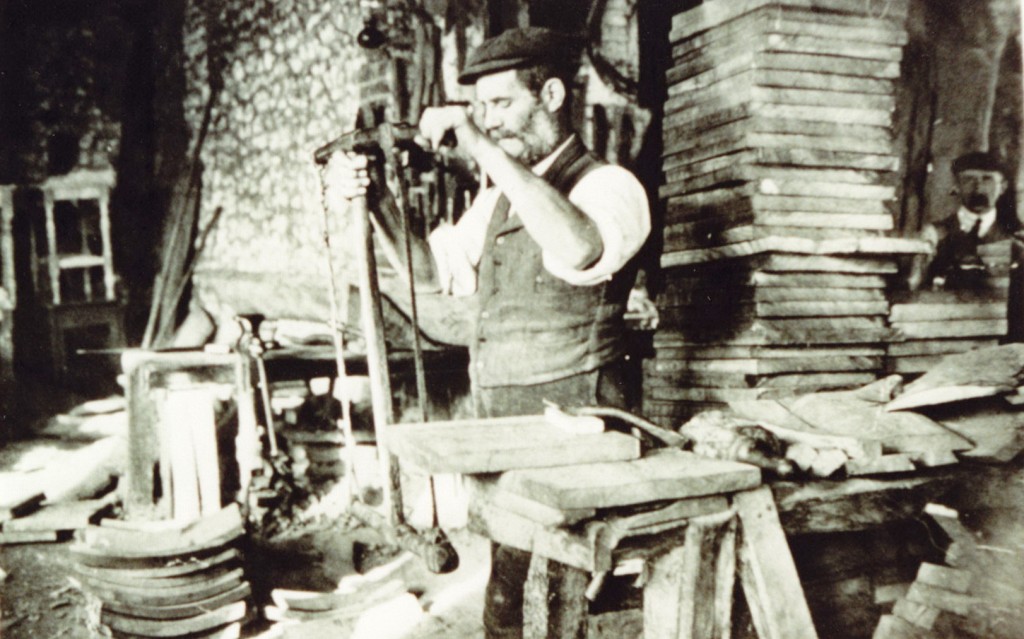

The workmen of the chair-making factory with some finished chairs stacked up beside them. If you can identify any of these men, please let us know. It is likely that the gentleman holding his hat and hence revealing his bald head is the owner/proprietor, perhaps Thomas Orchard or Albert Bray.

The workman here is boring out the legs of the chair. Two legs are firmly held in place on the bench by a combination of three pegs, a specially-shaped piece of wood between the legs and a wedge. The holes are cut out by a particular kind of centre-bit (a drilling bit with two side cutters) which enables the hole to be made without drilling right through the wood. The centre-bit is held against a pad which is fastened to the workmans’s chest, enabling the work to be done more quickly and safely than if it was operated by hand.

On the bench are some of the tools used in chair-making as well as some cores cut out by the centre-bit. An almost-finished Windsor chair is behind the bench.

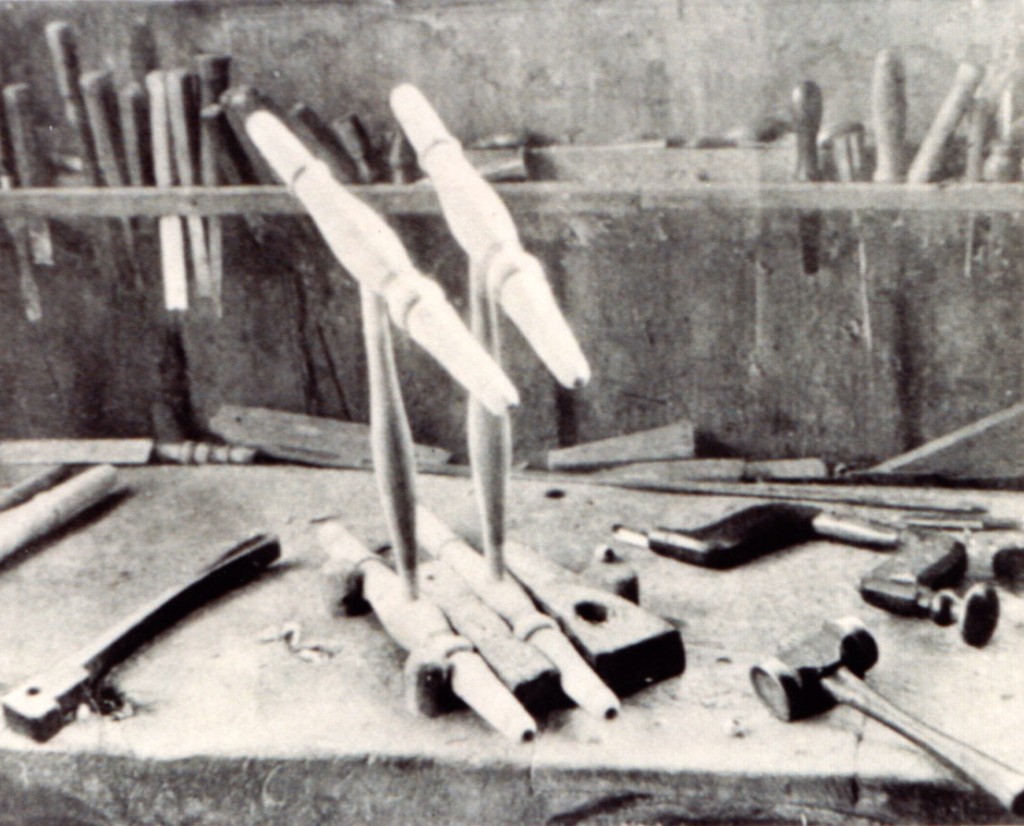

The chair legs and stretchers are being glued together. The arrangement of three pegs, specially-shaped piece of wood and wedge needed to hold the legs in place for boring out the holes is clearly shown here.

A seat has been cut out from the board and is being shaped with a band-saw worked vertically up and down while the seat is held firmly in position by a simple iron apparatus called a dog. The curved chair backs were cut out and shaped in a similar way.

The seats of the chairs are shaped or hollowed out with an adze (a cutting tool with a long handle and a thin curved blade). A number of seats are being planed out from a single board.