A talk by Alan Heasman – 27 June 2016

Its origins……….

Its increasing popularity……….

Its arrival in England……….

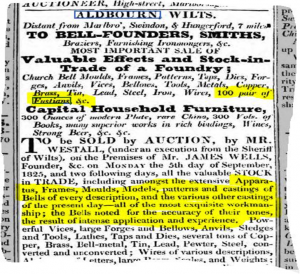

Its arrival in Aldbourne……….

The ‘boom’ years……

Its decline……………

Fustian

Is it fustian or fus’chan ?

I will (probably) stick with fustian

Origin

With respect to ‘The Old World’, it probably originated in EGYPT, along the Nile

EGYPT was a source of cotton supply to Europe before trading began with India & China

In particular , near Cairo was the city of FUSTAT where cloth was made–hence by centuries of use evolved ‘Fustian’

Flax (also known as linseed), the source plant for linen, was also grown in Egypt

Egypt – about C2nd AD

No doubt somebody had a ‘light bulb moment’ and decided to mix cotton and linen….

and produced a stronger cloth

Europe

- By the C12th ‘fustian’ was known in southern Italy, especially near GENOA, a trading port

- By C14th (Edward III) it was known in England

- Known to Chaucer ;

Names and References

- Fustane,fustain,fustayn,fusten,fustien,fustyn,fustin,fuschain,fusteyn,fustyyayine , fustyam, fusteem, fosten fustean..!!!

- Trinity College, 1200 ‘De meshakele of medeme fustane’

- Chaucer, 1386 ‘His clothinge was blakke fustyan ….’

- Privy Purse Expenses in 1501 ‘…….yerdes of white fustyan for sockkes for the Quene’

- Shakespeare 1586 ‘…the serving men in their new fustian’

In England

- For more substantial clothing (The Little Ice Age) the imported cotton yarn was mixed with wool both for clothing and padding

- From its use in padding, the word came into figurative use as meaning ‘pompous’, ‘pretentious’ or ‘superfluous’ words or made-up language e.g Shakespeare’s Twelfth Night Act 2 Scene 5: Malovia: “I may command where I adore, But silence like a Lucrece knife, With Bloodless stroke my heart doth gore, M.O.A.I. Doth sway my life”

- Fabian: “A fustian riddle”.

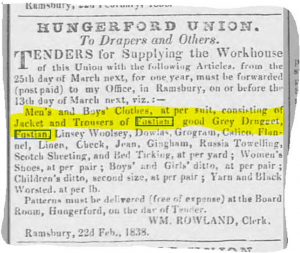

Fustian

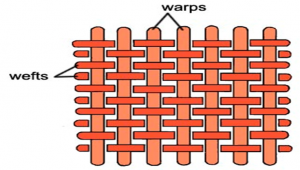

- A stout fabric of cotton and linen/flax or

- A fabric of stout twilled cotton and low quality wool with a short nap or pile

- The key development was to use the strong linen as the ‘warp’ (the longitudinal threads) and cotton as the ‘weft’ , (the latitudinal threads)

- Variations in the quality of the line & the cotton influenced the resultant material, making it either light and decorative or ‘stout’ and functional

Aldbourne

- Record of a ‘weaver’ in the village in 1630s

- By 1640s, EDWARD WITTS , probably of Dutch origin, arrived in the village and is recorded as a fustian maker

- By late 1600s, several other families were involved

Weaving fustian in Aldbourne

- Imported cotton –hence need for good transport

- Grow flax locally ? No evidence but possible, or it was imported

- Hand looms , so at least some production in ‘cottages’ as well as the ‘factory’

- Material produced was an ‘alloy’ of either linen & cotton or linen & wool and possible other combinations

- The linen was a common factor for its strength

The Witts

- Edward probably arrived from Holland in 1640s; married Jane (?Joanne) Hinton (daughter of a fustian maker) in 1649; they had five sons; in 1666 Edward issued a trade token featuring a shuttle indicating his trade

- They probably lived in South Street at some time but had work premises elsewhere……..

- Edward & Jane Witts dominated the fustian business in Aldbourne for three decades

- Edward died of a ‘dead palsy’ ( ? A stroke) in 1688

- In his will he left ‘…fustian pieces in several places £140 … And fustian and scotch yarn in his chambers value £40… also ‘…looms and work still on them value £14 ’.

- Total value £194 ..about £ 17,000 at 2015 values but the purchasing power then would be even greater !

- Calendering or calindering was part of the process for making fustian; it involved ‘ironing’ the material between rollers to smooth it out; calender from French colandre – roller

- Edward Witts’ ‘callinder house’ was situated in a building which had been part of the stables of the George Inn on the Green

- In his Will Edward left the ‘callinder house’ to his youngest son Benjamin….. but only after the death of Edward’s wife Jane !

- Edward also bequeathed ‘..one half of my fustian callinder which now standeth in the Callinder house….to his son Richard Witts’

- So we can surmise that Edward owned half of the ‘callinder’ equipment perhaps shared with another fustian maker…..

The Wittes Callinder House

The Boom Years

- Under the Witts’ family management the business thrived.

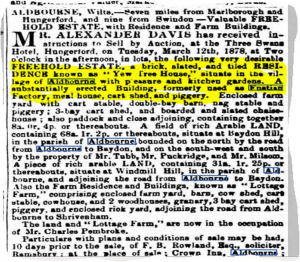

- Early in the 1700s, a ‘manufactory’ was built in South Street, no doubt on land owned by the Witts family –hence ‘Witts Piece’ as it is today

- Sufficient trade that in 1709, inhabitants of Aldbourne supported a plan to make the Kennet navigable from Reading to Newbury, granted in an Act of 1714. That helped incoming raw goods and departing finished goods to London although transport by carts still continued

Aldbourne Fustian Manufactory

The Boom Years

- Good trade continued well into the 1700s

- The ‘factory’ had its roof raised to accommodate a third working level but many looms continued to be used in cottages

- Then ‘disaster’; the terrible fire of 1760 destroyed many buildings and their contents

- Joshua Shepherd , one of the smaller fustian makers went bankrupt in 1761 followed by another, Edward Read, in 1762

- The village had barely recovered when the fire of 1777 destroyed more fustian equipment and stores

The Beginning of the End

- These two disasters combined with the growth of large scale ‘mechanised’ mills in the North of England started the decline of fustian making in Aldbourne

- Nevertheless there were still six named manufacturers in 1792 including the Pizzie family

- In 1778 , Caleb Pizzie ‘cotton manufacturer of Aldbourne….married Patience Flower, spinster of Overton….’

- In 1797 Joseph Pizzie was a fustian maker (& grocer!)

Aldbourne Fustian in Decline

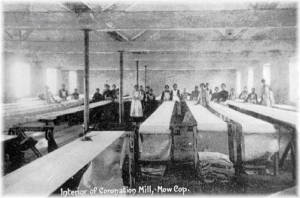

- As more industrialised production grew especially in Cheshire e.g. Mow Cop, & in Lancashire, small scale production began to decline

- Listed makers in Aldbourne fell from seven in 1791 to five in 1809 and to only one in 1830; the 1851 census recorded four fustian weavers and this fell to just two by 1881

200 Years of Fustian ‘Makers’ in Aldbourne

- 1647 Edward Hinton – Fustian Maker*

- 1655 Benjamin Lawrence –Fustian Weaver

- 1687 Edward Witts – Fustian Maker *

- 1708 Edmund Barrett – Fustian Weaver

- 1714 Edward Witts – Fustian Maker

- 1777 William Gwyn – Fustian Manufacturer

- 1791 Thomas Liddiard –Fustian Weaver

- 1791 George Gwynn –Fustian Weaver

- 1795 William Cumner- Fustian Maker

- 1797 Joseph Pizzie – Fustian maker

- 1815 Martin Palmer- Fustian Maker

- 1823 Thomas Palmer – Fustian Manufacturer

- 1833 Stephen Gould – Fustian Weaver

- 1842 Broome Witts – Fustian Manufacturer

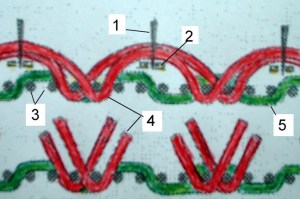

Weaving Fustian

Fustian Weaver; about a yard or so in a 12 hour day

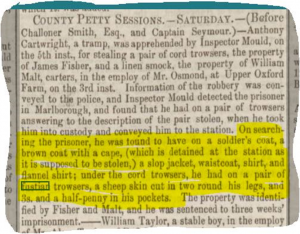

Types of Fustian

- Plain strong fabric – no cutting

- Strong hard wearing with a ‘brushed’ finish e.g. Moleskin

- Strong hard wearing with a cut ‘ribbed & brushed’ finish e.g. Corderoy

- Softer, cut & brushed and made entirely of cotton e.g. Candlewick – a good insulator , used for bedspreads

- These days ‘ polyester & cotton’ blend could be considered the modern ‘fustian’ ; tougher, cheaper, washes well and facilitates multi-colouring

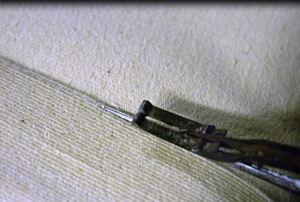

Fustian Cutting

- A two yard length of cloth two feet wide could take an hour to cut

- Best quality velveteen required 40 cuts in each inch of width ! Very tedious and exacting work requiring a lot of walking alongside the length of cloth

- A skilled worker might operate with a knife in each hand

- In mid C19th , ‘piece’ work/payment was introduced ; a worker could earn 15 shillings a week for ten hours work each day

A Cutting Factory

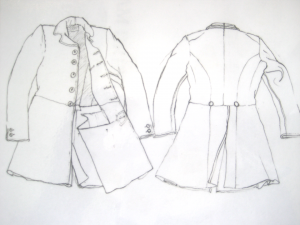

Fustian Jacket

Fustian jacket- probably used as a hunting jacket; brass buttons; no outer pockets but two deep inside pockets; made in Swindon; now part of collection at Museum of English Rural Life (MERL), Reading.

This is a rougher fustian jacket; outside pockets; horn/wood buttons; bought from a shepherd in Hampshire in about 1914 !

Now in the MERL collection in Reading

Fustian Miscellany

- 1791- Thomas VOKINS a fustian weaver, perished in the snow whilst returning home from Baydon (Source: Bath Chronicle 17 March 1791

- Vokins is not a common name but from 1882 until 1997 there was a large departmental store in Brighton specialising in drapery & haberdashery, so there may be a ‘tenuous link’ to Aldbourne …?

The Village Wedding

In 1910, Charles McEvoy wrote & produced his famous village play. Mrs Mabel Stacey made the clothes because she was a skilled seamstress. Allegedly one of the actresses asked her ‘ What be I gwine to wear then ?’ expecting some fine clothing . But, much to the disgust of the actress, Mabel replied ‘ Brown jane’ .

‘Brown jane’ was a common tough material, a survival of fustian and maybe linked to ‘jean’. Charles McEvoy insisted ‘ rough simplicity must be preserved’.

Summary

Aldbourne rightly claims fame to bell founding for over 200 years but it only required a limited and skilled workforce

Whereas fustian weaving was a mainstay of employment for many more villagers, probably as many as 150 at its height, especially the women and children , also for 200 years.

Thanks

My thanks to Dr & Mrs Rayner for allowing access to the Fustian Factory

And to Gill Reeve for access to her copy of Edward Witts’ Will and the photos of her house

And to John Dymond for some supplementary information from other village Wills